Why a Personalized Knee?

Here are some key differences to better understand why it is important to have an implant designed specifically for you.

If It's Not Conformis, It's Not Patient-Specific

• The unicity of your knee makes it essential to mimic its natural joint lines. While Off-the-shelf knee implants are designed based on a set of pre-determined measurements, and the “closest fit” is selected at the time of surgery, Conformis reproduces accurately your specific knee and the neutral mechanical alignment of your body (called HPA alignment, standing for Hip, Knee, Ankle).

• Because off-the-shelf implants aren’t designed to your specific anatomy, surgeons often have to compromise on implant fit, rotation, and alignment. These compromises can cause pain or discomfort after surgery and help explain why 1 in 5 patients aren’t satisfied with their standard implant. We don’t believe in forcing your body to match the implant, but rather creating an implant matching your knee.

• Over the years, we have developed a full range of knee protheses that will match your unique anatomy, providing a more natural feeling, better fit, better shape, and easy motion, leading to less pain, better flexion and extension as well as stability.

Patient Advocates

Conformis Patient Advocates are real patients who are living with a Conformis knee replacement (some more than one!). You may have questions that can best be answered by someone who has had a similar knee joint replacement experience.

Our Patient Advocates are here to help answer questions about full knee replacement recovery and more.

Dave's knee pain was so severe prior to surgery that it kept him off the golf course and dance floor for years. Now that he has two patient-specific knees, he is able to dance and golf again.

Meet Dave »Darvina was always active, as a downhill skier, cheerleader and hiker. She had her total knee done as an outpatient procedure and was home the same day.

Meet Darvina »Yoga instructor Mike also enjoys climbing trees in his spare time. When his past injuries caused his knee to deteriorate to the point of knee replacement, he discovered the difference a patient-specific knee can make.

Meet Mike »Our unique process

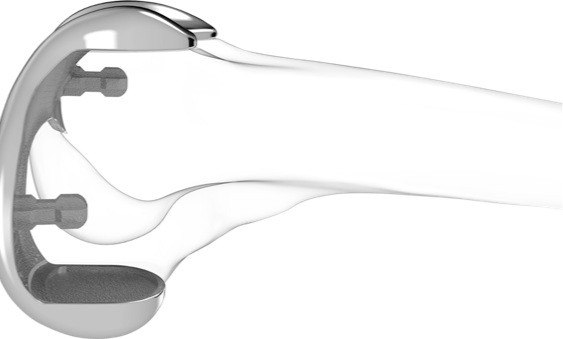

Our proprietary software uses CT scan data to design an implant and set of instrumentation that will match precisely to the 3D model of the knee, correcting the data for any underlying arthritic deformity such as bone spurs, cysts or flattening of the joint.

Our disposable, patient-specific iJig® instrumentation is manufactured using the latest in 3D printing technology, and our single-use implant kit is delivered pre-sterilized a few days before surgery, removing the inventory from hospital shelves. This also allows for rapid design improvements that can be implemented immediately.

Products

We offer patient-specific total and partial knee replacement options as well as 3D printed surgical instrumentation for each and every case.

1. In a study by W. Kurtz titled “Patient-Specific Knee Replacement Implants Preserve Bone and Decrease Blood Loss & Swelling” presented at the 2013 BASK Annual Meeting, comparing 66 iTotal patients with 66 patients receiving one off-the-shelf implant brand (Zimmer NexGen), thickness of the femoral (distal and posterior medial/lateral), and tibial (medial/lateral) resections were measured intra-operatively. The average total of all bone resection measurements for iTotal was 27% (14mm) less than for the off-the-shelf total knee. Additionally, the total thickness of the iTotal implants was 25% (15.7mm) thinner on average than the off-the-shelf implants.